- PRODUCTS商品櫥窗

- All products

- Air Compressors

商品明細

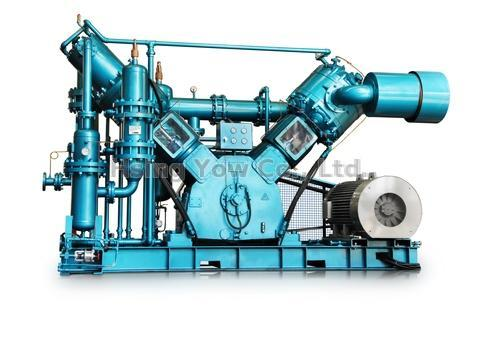

Oil-free High Pressure Reciprocating Compressor

- 料號:VFW Series

-

● High efficiency models● Greater compression efficiency● More air generated● Less power bills● Special cooling and moisture design

商品詳細介紹Product Introduction

● High efficiency models

● Greater compression efficiency

● More air generated

● Less power bills

● Special cooling and moisture design

The Fusheng VFW oil-free, high-pressure, 100% clean air compressor series is specially designed for the PET blow molding industry. Drawing from the wealth of experience gained from long-term operations in varying conditions, the compressors are engineered to be highly efficient and reliable as they provide a stable supply of compressed air for blow molding. The series ranges from 50 to 300HP with discharge pressures ranging from 25 to 40 kg/cm2 and is accommodated for variable injection volumes. The VFW series has a built-in user-friendly interface, touch-screen panel, and PLC control system. The compressor is equipped with multiple alert systems and safety features for better overall control. Operating parameters, status, and servicing instructions are shown on the monitor to provide the user with important data concerning periodic and preventive maintenance.

The Features of Products:

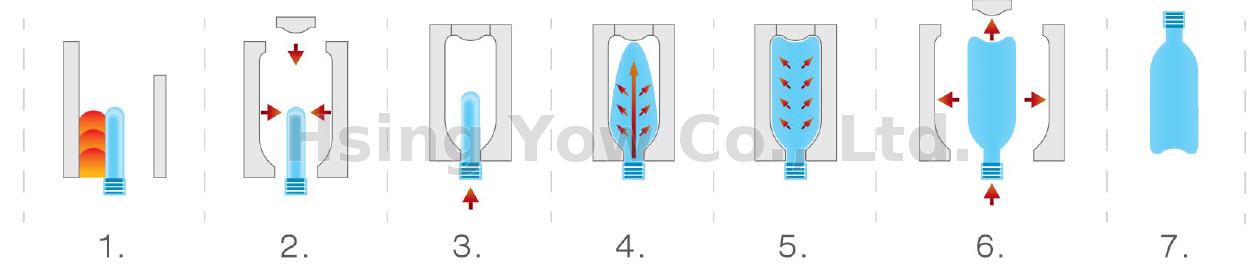

● PET/PP bottle forming process

1. Oven is steadily heated to provide the forming temperature evenly distributed over the bottle preforms.

● PET/PP bottle forming process

1. Oven is steadily heated to provide the forming temperature evenly distributed over the bottle preforms.

2. The mold is locked onto the transmission mechanism for bottle forming.

3. Blow nozzle is inserted into the preform.

4. Air is injected into the preform to form the bottle.

5. The mold is opened.

6. The finished product is unloaded.

7. Mold stripping.

● Applications of blow molding

- The demand for (PET) bottle blowing is growing.

- VFW series compressors are designed exclusively for PET bottle blowing machines.

- The air compression process is 100% completely oil-free, allowing for the supply of oil-free, clean air.

- PET bottles and containers are recycled massively as the idea of environmental protection grows.

- The pressure of compressor is regulated between 25 and 40 kg/cm2G. making the series suitable for various industrial oil-free applications.

- The primary applications are, for example, pharmaceuticals, food and packaging, paper making, textile, petrochemicals, bacteria culturing, chemical analysis and electronics/high-tech manufacturing.

Completely Oil-Free, Clean Pressurized Air

Design criteria for the body

● Driven by the crankshaft of oil pump, no additional power needed.

● Stainless steel suction / discharge valves for high strength and long service life.

● Pistons made of aluminum alloy for effective weight reduction and dynamic balance.

● Special coating on cross-head for better wearing resistance and smoother operations in the long run.

● Single-action design for the 2nd and 3rd stages, thus reducing the number of valves needed.

● Mono-block 2nd and 3rd stage pistons, no need for 3-stage air-tight design.

● Compressor body encapsulated in a water jacket for effective cooling and increased life of parts and components.

● Piston rings made of PTFE, special formula that increases wear resistance and service life.

● Unique air intake baffing design for lower noises, smaller impulses and longer service life.

Complete details of equipment design

● μ - level air filtering accuracy, suitable for various industrial environments.

● All-in-one design for easy shipping by cargo container.

● Integral cooling water circulation design for easy pipe work installation.

● Designed for 20 to 30 years of trouble-free use when operated in normal conditions.

● Low-rpm design. i.e. longer service life for parts and servicing cycles.

● Special high-performance cooling design for more compact size, greater performance and higher efficiency.

● Latest defogging design and optimized condensation separation for greater compression efficiency.

● Wide range of work pressure allows regulation of pressure between 25 and 40 kg/cm2G depending on operating conditions.

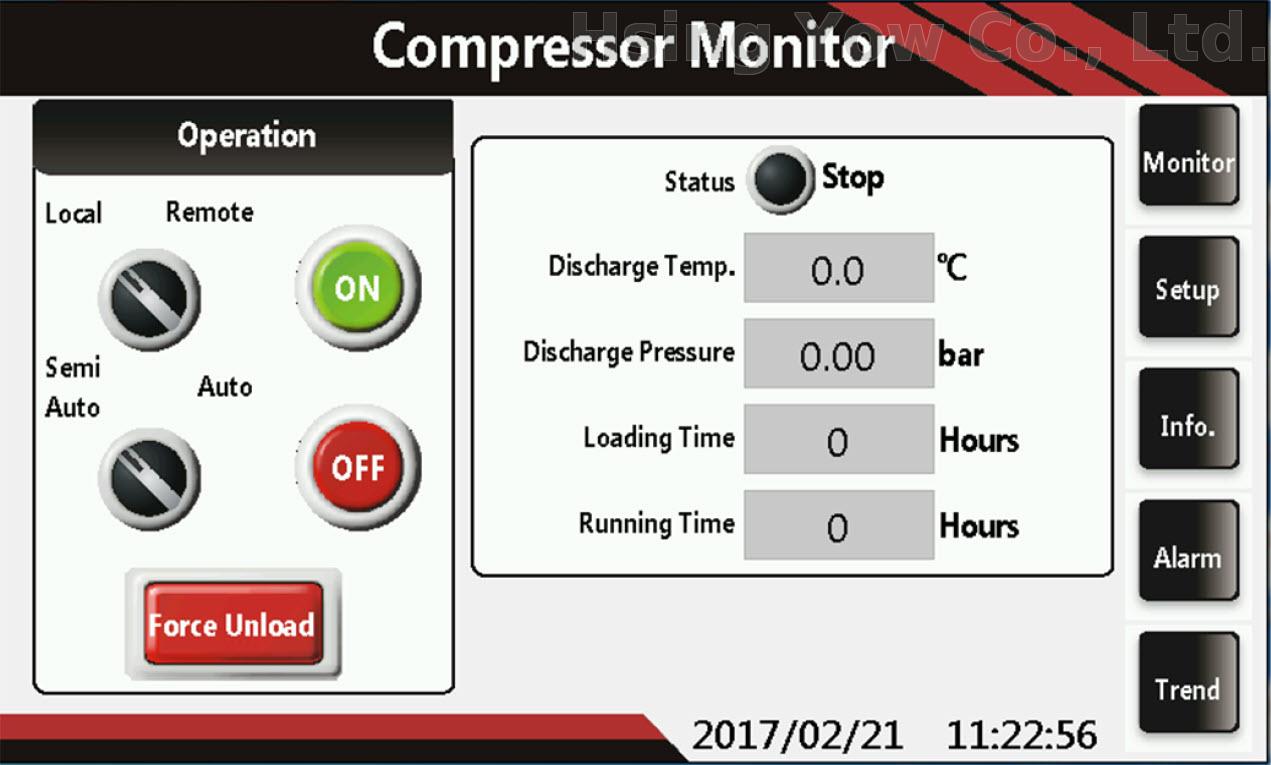

Our Standard Control

● Voltmeter

Our Standard Control

● Voltmeter

● Ammeter

● Power supply indication

● Water loss protection

● Oil loss protection

● Operation timer

● Electric overloading protection

● Emergency stop button

● 3rd high temperature protection

● Auto / semi-automatic control switching

● ON / OFF switch and indication (Additional functions are available as options on demand)

Maintenance and Servicing

● Complete after service system across the globe.

● Optimization of service solutions by predicting service needs via indicators and trends.

● Use of high-strength composite materials for greater reliability of parts and increased life of components.

● Reciprocal compressor features ease of maintenance and all components are easy to remove for servicing.

● Large bore and low rpm design features light loading and prolonged service life of valves, piston rings and bearings.

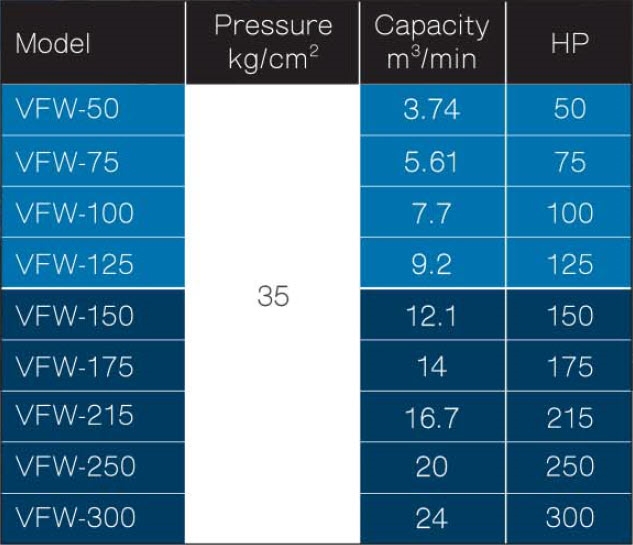

Specification

商品注意事項Product Notes